Top Notch by Design New Egypt Nj

FINISH

The VALUE of Factory Finish

Protect your investment and do the job RIGHT! The value of factory finished log siding vs. the risk and cost of problems in the field after installation...

The first thing that wood experts like the Western Red Cedar Lumber Association will tell you is that all wood siding - even cedar log siding - needs to be sealed on all six sides prior to installation and then re coated as needed on the face for the lifetime of the wood.

FINISH SIDING PRIOR TO INSTALLATION "Before installation (job site), applying a finish to all surfaces (including ends) is recommended. Factory applied finishes are best. They ensure the best performance of the finish. The type of coating will be determined by final finish and look selected. The finish protects the wood from moisture absorption and UV degradation, helps prevent staining caused by mildew and extractives and will increase the service life of top coats."

from WRCLA How to Install Western Red Cedar Siding

We interviewed Brandon Stendal- owner of Stone Valley Painting, LLC. and a customer of ours and asked- "What is the value of factory finish?"

"Usually we are only finishing the face of the building. For us- a commercial painter- to prime coat 6 sides in the field takes about twice as long as coating the face alone after installation. We charge $50hour commercially so the price immediately doubles. We primed all 4 sides of about 833 sqft of your wood siding and it took 2 guys about 8 hours to do this job. It took 5 gallons of primer to coat it (between $25 and $30 per gallon) and we had to rack it at our own warehouse and then transport to the jobsite. I would actually prefer my customers to get a factory finished primer coat and then have me do the final coat in the field- that is the best wood siding performance option. That may not sound like it is good for business but long term, happy customers are my business!"

We agree completely.

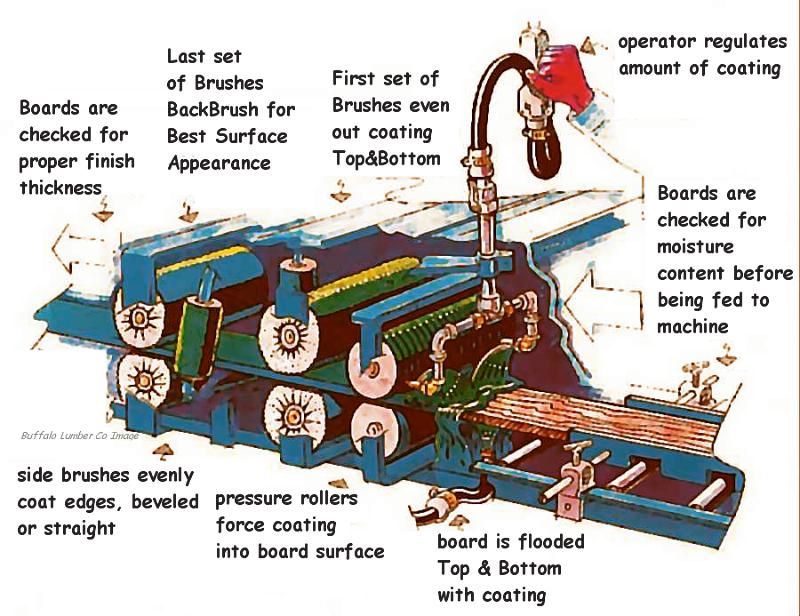

Factory finishing coats 4 of six sides - You get the face, the back and both side edges, the butt ends need to be sealed when installed on the jobsite.

If you are going to do the job right- you can't do it better (or cheaper) than the machines. If you are planning to stain instead of paint- the number of gallons needed per square foot virtually doubles. You do not have to apply a final coat to the face after installation but you had better have a large, well ventilated area with racks for the wood siding to dry - usually 3-7 days depending on humidity and finish choice.

The fact is that sealing the wood on all six sides prior to installation is the single most important thing you can do to ensure the long term performance of your wood siding- factory finishing saves the headache factor (literally) and is the first step to doing the job right.

What they are not factoring is the COST and TIME of finishing the job in the field or more aptly put - the cost of field finishing your log siding THE RIGHT WAY! The RIGHT WAY is to apply finish to all 6 sides of the wood prior to installation in order to protect it from moisture damage. As you can imagine applying stain to 6 sides of a stick of wood in the field is a time consuming (and money consuming) process.

It is usually done by the installers (who are not trained finishers) and it is a big job. Imagine you are an installer at a job site with 2000sq feet of hewn log siding that has not been finished and you have to finish all 6 sides before installation. Rough estimates of 2x8 or 3x8 log siding require about 3600 lineal feet to cover 2000 square feet of space.

To put this into perspective in order to stain both sides you are going to be finishing 1.4 miles of wood. You will need a place to store 1.4 miles of wood and you will need to dry 1.4 miles of wood without dirt or bugs or anything getting into the finish during this process. Chances are you are not going to have the proper equipment (or space) to do the job right and if you try the expenses are going to mount up.

So you have a meeting with the homeowner and decide the best way to handle this is to install the wood with no finish and then finish the face after installation in order to save money. Many homeowners feel that risk is worth the savings however we disagree. The risk is that water will get trapped behind the wood at some point during the home's lifespan. When this happens the log siding WILL ROT. There are no exceptions to this rule- if water stands on wood it will rot.

The reason every piece of literature on the subject says to finish all six sides prior to installation is that siding - especially pine siding - is extremely susceptible to rot. If rot begins to occur on the back side of your siding you will have no way of knowing until it is too late. Too late being when the rot shows up on the face of the wood. Rot is contagious- if it shows up on the face of the wood chances are it has gone the other way as well.

We have documented cases of wood siding that has begun to rot and has taken out the walls behind it as well as the siding in front. In those cases the entire wall has to be replaced not just the siding itself. The cost of fixing such problems in the field run into the tens of thousands of dollars. Some of you will be thinking "well that is a worst case scenario" and you would be right however think about it for a minute. In your lifetime how many people have actually taken the time to do a job exactly right?

If you have the same experience as we do you will realize that most people (including installers) take shortcuts. Shortcuts cause worst case scenarios to occur. Sitting in my chair I have spoken to people directly who have had improper installation techniques cost 10 times more to fix than if they had used proper methods in the first place. The number one cause of problems in the field? Water damage- the number one cause of water damage in the field? Improper field finishing and installation. If you think I am trying to scare the living daylights out of you, you are exactly right.

I am trying to scare you into making sure things are done exactly right. We feel the risk is too great for our customers. If we are more expensive than the guys down the road it is because doing a job exactly right usually costs more up front than the cheapest option.

The truth may not be what you "want" to hear but remember if it's worthwhile to do: It costs 3 times as much and takes 3 times as long as you originally thought it would. It costs 10 times as much to fix a screw up as to do things right in the first place! The Question Is - Can You afford Not to Factory Finish?

At the end of the day how much is your peace of mind really worth? Chris Buffalo of Buffalo Lumber Company has consulted on over 20,000 wood projects, bid over 10,000, sold over 2,000 and visited over 200 jobsites nationwide. His credentials are "Been there done that thousands of times". It's not Bull it's Buffalo ;-)

Top Notch by Design New Egypt Nj

Source: https://www.buffalo-lumber.com/log-siding/

0 Response to "Top Notch by Design New Egypt Nj"

Post a Comment